Recently, our company received a project. The customer’s equipment for this project is a dissolving furnace with a temperature of 1300 ° C. Previously, the gas was pumped out and pretreated to measure oxygen. Because the temperature and pressure of the pumped gas have changed, the measured oxygen content is not the real-time oxygen content in the furnace, and the product quality cannot be controlled based on this oxygen content data.

Due to the special packaging technology of our company’s Nernst oxygen probe, it can withstand high temperatures of 1400 ° C, so it can be directly inserted into the furnace at 1300 ° C, and the accurate oxygen content in the furnace can be measured in real time without the cumbersome pumping pretreatment process.

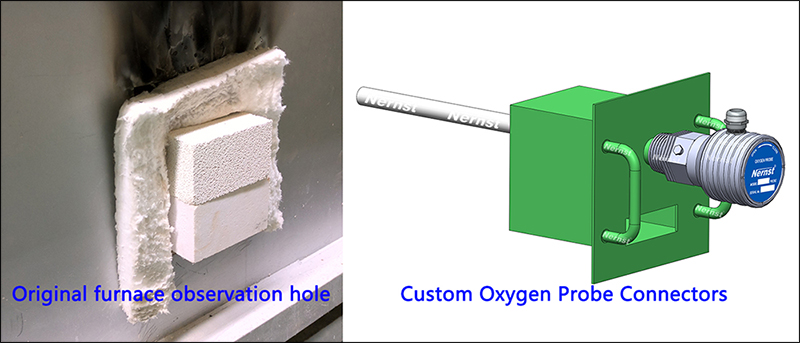

However, the customer’s existing furnace cannot be re-opened to install Nernst’s high-temperature oxygen probe. Our company specially designed and customized the oxygen probe connecting parts for the customer, without changing the original state of the furnace, which can not only meet the oxygen probe installation requirements, but also retain the original observation hole. The customer is very satisfied with our company’s scheme design ability and product performance.

Post time: Sep-24-2024