The Acid Dew Point Analyzer is designed to determine the lower temperature limit of waste heat containing acidic gases. It finds application in industrial boilers, power plant boilers, petroleum refineries, and heating furnaces, which typically utilize fossil fuels such as natural gas, refinery dry gas, coal, and heavy oil. These fuels invariably contain varying amounts of sulfur. During the combustion process with excess oxygen, SO2 is produced. In the presence of excess oxygen in the combustion chamber and under normal excess air conditions, a small portion of SO2 further reacts with oxygen to form SO3, along with Fe2O3 and V2O5 (present in flue gas and on heated metal surfaces).

How does the Acid Dew Point Analyzer work?

When burning high-sulfur fuels, a portion of the SO2 formed after combustion is further oxidized to SO3, which then combines with water vapor in the flue gas to form sulfuric acid vapor. The condensation temperature of sulfuric acid vapor in the flue gas is referred to as the acid dew point, which is significantly higher than the water dew point. The higher the SO3 (or sulfuric acid vapor) content in the flue gas, the higher the acid dew point, which can reach 140~160°C or even higher.

Conductivity Sensor Technology:

The conductivity cell consists of a pair of electrodes. A stable voltage is applied across the electrodes, and changes in the liquid resistance within the conductivity cell cause corresponding changes in the current through the measuring electrode, adhering to Ohm's Law. By substituting resistivity with conductivity and resistance with conductance in metals, the conductivity and conductance are used to represent the object's conductive capability, thereby enabling conductivity measurement.

Technical Features:

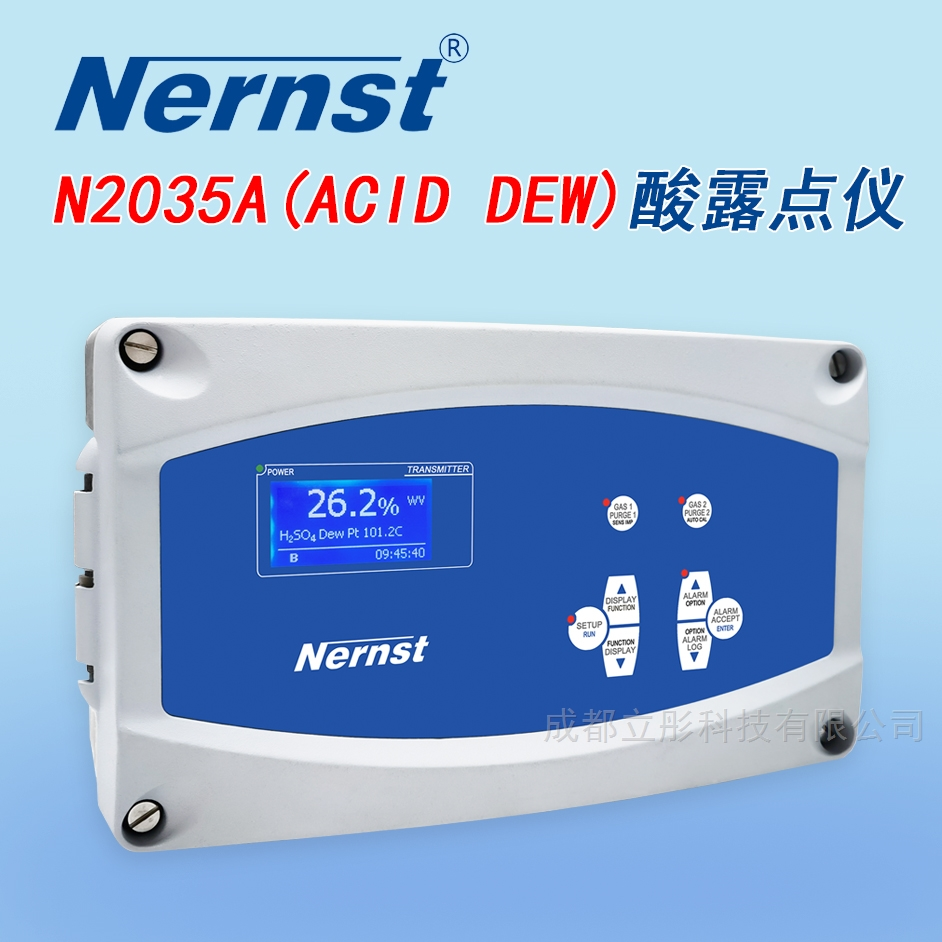

Probe Measurement: A single instrument can simultaneously measure oxygen content, water dew point, moisture content, and acid dew point.

Multi-channel Output Control: The instrument features two 4~20mA current outputs and computer communication interfaces RS232 and RS485.

Measurement Range: 0°C~200°C acid dew point, 1ppm~ oxygen content, 0~ water vapor, -50°C~100°C dew point, and moisture content (g/kg).

Alarm Settings: The instrument has one general-purpose alarm output and three programmable alarm outputs.

Automatic Calibration: The instrument automatically monitors and calibrates each functional system to ensure measurement accuracy.

Intelligent System: The instrument allows for human-machine interaction and performs various set functions according to predefined settings.

Display and Output Functions: The instrument boasts a powerful display for various parameters and robust output and control functions for these parameters.

Variable Parameter Selection: Based on different fuels (lignite, washed coal, pulverized coal, natural gas, blast furnace gas, heavy oil, various grades of fuel oil, etc.) with varying sulfur content generating SO2 and the conversion rate of each fuel to SO3, the instrument directly provides high-precision combustion flue gas acid dew point values for each fuel.

From the above introduction, it's evident that each method has its own advantages and disadvantages. The Acid Dew Point Analyzer, with its high resolution and sensitivity, has gained popularity in denitrification monitoring. The ion-selective electrode method in offline manual sampling analysis is fast, accurate, and boasts strong anti-dust interference capabilities, making it suitable for on-site testing. Currently, online monitoring in power plants is less than ideal, necessitating supplementary offline measurements and periodic testing to verify online measurement data and enhance monitoring accuracy.

Post time: Mar-27-2025